PPCS64 Plenum Pulse Bag Filter

Plenum Pulse Bag Dust Collector is advanced high efficiency dust collector which is introduced from the United States Fuller Company. It integrated the advantages of all kinds of bag dust collector of chamber blow and injection pulse soot cleaning, overcome the chamber blow soot cleaning strength is not enough, injection pulse soot cleaning and filtering simultaneously, thus expanding the application range of bag dust collector, because the structure of this dust collector has its characteristics, so improving the dust collecting efficiency, prolong the service life of the filter bag.

Aerating Box Pulse Bag Dust Collector can be widely used in dust collecting system of cement plant of crushing, packaging, clinker cooling machine and all kinds of milling machine. If it is used for coal milling dust collecting, please add flame-proof and explosion-proof measures, dust collector's structure will change accordingly. It is also suitable for high dust content gas dust collecting. Such as grinding system with O - Sepa powder concentrator, dust content of gas is as high as more than 1000 g/m3 (standard). If you choose this series of dust collector is no need to set cyclone dust collector to do the first level dust collecting. Besides used in the cement industry, can also be applied to metallurgical, chemical, mechanical and civil boiler flue gas dust collecting. This series dust collector filter bag material, usually use polyester fiber needle felt, allows continuous use under temperature less than 120 ℃, if the temperature rise, should choose other filter material, or add cooling measures should be taken before exhaust gas entering the dust collector.

Aerating Box Pulse Bag Dust Collector for the outdoor type of different room number and every room of the sack, composed of a variety of different specifications. Each room has 32, 64, 96,128 bags four kinds. Whole series of a total of 33 kinds of specifications, the filter bag is 130 mm in diameter; length of the filter bag has two kinds of 2450 mm and 3060 mm. This series of dust collector can be negative or positive pressure operation, its mechanical structure without any change. The dust collecting efficiency can reach more than 99.9%, after cleaning the dust concentration of the gas is less than 100 mg/m3 (standard), main technical performance of this series dust collector, please check the attached table. This series of dust collector could be used in cold area, if the outdoor temperature is -25 ℃ or less, need to add heating device, dust collector shell is also need to add insulating layer.

●Structure and Work Principle

Aerating Box Pulse Bag Dust Collector consists of shell, ash bucket, ash discharge device, support part and pulse soot cleaning system, etc. The dust first hit the incline plate in the middle of the inlet and outlet, the gas will turn the direction and flow into the ash bucket, due to inertia effect, the coarse particles of the gas directly fall into the dust bucket that makes dust collecting in advance. The airflow into the ash bucket changes direction and upward through filter bag which with the internal skeleton, the dust will be collected on the surface of the filter bag. After purification, the gas will get into the upper clean room in the filter bag chamber, gather into the air outlet pipe and exert. PPC32 type dust collector inlet set at the bucket, the dust first hit the baffle plate at the end of the upside air inlet, and other work principle is as above one. Dust collecting bags in the chamber are divided into several rows, according to a given time interval to clean dust bag in each row in turn. When the pulse valve opens, the filter bag is sprayed into the high pressure air immediately, in order to clear the dust on the surface of the filter bag. Each row of filter bag pulse spray width and soot cleaning cycle are controlled by soot cleaning program controller with automatic continuous control. Dust collector structure and working principle to check the appended drawings continuously.

Aerating Box Pulse Bag Dust Collector can be widely used in dust collecting system of cement plant of crushing, packaging, clinker cooling machine and all kinds of milling machine. If it is used for coal milling dust collecting, please add flame-proof and explosion-proof measures, dust collector's structure will change accordingly. It is also suitable for high dust content gas dust collecting. Such as grinding system with O - Sepa powder concentrator, dust content of gas is as high as more than 1000 g/m3 (standard). If you choose this series of dust collector is no need to set cyclone dust collector to do the first level dust collecting. Besides used in the cement industry, can also be applied to metallurgical, chemical, mechanical and civil boiler flue gas dust collecting. This series dust collector filter bag material, usually use polyester fiber needle felt, allows continuous use under temperature less than 120 ℃, if the temperature rise, should choose other filter material, or add cooling measures should be taken before exhaust gas entering the dust collector.

Aerating Box Pulse Bag Dust Collector for the outdoor type of different room number and every room of the sack, composed of a variety of different specifications. Each room has 32, 64, 96,128 bags four kinds. Whole series of a total of 33 kinds of specifications, the filter bag is 130 mm in diameter; length of the filter bag has two kinds of 2450 mm and 3060 mm. This series of dust collector can be negative or positive pressure operation, its mechanical structure without any change. The dust collecting efficiency can reach more than 99.9%, after cleaning the dust concentration of the gas is less than 100 mg/m3 (standard), main technical performance of this series dust collector, please check the attached table. This series of dust collector could be used in cold area, if the outdoor temperature is -25 ℃ or less, need to add heating device, dust collector shell is also need to add insulating layer.

●Structure and Work Principle

Aerating Box Pulse Bag Dust Collector consists of shell, ash bucket, ash discharge device, support part and pulse soot cleaning system, etc. The dust first hit the incline plate in the middle of the inlet and outlet, the gas will turn the direction and flow into the ash bucket, due to inertia effect, the coarse particles of the gas directly fall into the dust bucket that makes dust collecting in advance. The airflow into the ash bucket changes direction and upward through filter bag which with the internal skeleton, the dust will be collected on the surface of the filter bag. After purification, the gas will get into the upper clean room in the filter bag chamber, gather into the air outlet pipe and exert. PPC32 type dust collector inlet set at the bucket, the dust first hit the baffle plate at the end of the upside air inlet, and other work principle is as above one. Dust collecting bags in the chamber are divided into several rows, according to a given time interval to clean dust bag in each row in turn. When the pulse valve opens, the filter bag is sprayed into the high pressure air immediately, in order to clear the dust on the surface of the filter bag. Each row of filter bag pulse spray width and soot cleaning cycle are controlled by soot cleaning program controller with automatic continuous control. Dust collector structure and working principle to check the appended drawings continuously.

PPCS32, PPCS64 Plenum Box Pulse Bag Dust Collector Technology Performance Tables

Type and Technical Parameters | PPCS32-3 | PPCS32-4 | PPCS32-5 | PPCS32-6 | PPCS64 -4 | PPCS64 -5 | PPCS64 -6 | PPCS64 -7 | PPCS64 -8 | |

Airflow (m3/h) | 6900 | 8930 | 11160 | 13390 | 17800 | 22300 | 26700 | 31200 | 35700 | |

Filter Speed (m/min) | 1.2~2.0 | |||||||||

Total Filter Area(m2) | 93 | 124 | 155 | 186 | 248 | 310 | 372 | 434 | 496 | |

Net Filter Area (m2) | 62 | 93 | 124 | 155 | 186 | 248 | 310 | 272 | 434 | |

Dust Collectors Room | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 | |

Filter Bags | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 | |

Dust Collector Resistance (Pa) | 1470-1770 | |||||||||

Inlet Dust Content (g/m3 ) (standard) | <200 <1000 | |||||||||

Outlet Dust Content (g/m3 ) (standard) | <0.1 | |||||||||

Negative Pressure of Dust Collector (Pa) | 5000 | |||||||||

Soot Cleaning Compressed Air | Pressure (Pa) | (5~7)×105 | ||||||||

Air Consumption (m3/mm) | 0.27 | 0.37 | 0.46 | 0.55 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | |

Pulse Valve (Solenoid Valve) | Qty | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

Size (inch) | 1 ″ | 2 ″ | ||||||||

Lift Valve (cylinder) | Qty | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

Type (mm)s | Lift Valve Diameter φ460,Cylinder Diameter φ63 | Lift Valve Diameter φ595,Cylinder Diameter φ100 | ||||||||

Rigid Impeller Feeder | Feeding inlet 300×300mm,Height 450mm | Rotate Speed 30.31r/min,Speed Reducer Motor 1.1KW Qty 24 m3/h | ||||||||

Screw Conveyor | Type | Diameter φ300,Qty 30m3/h(filling φ=0.7) | ||||||||

Speed Reducer Motor | TypexWD2.2-5-1/43,Power2.2kw | |||||||||

Air Slide Conveyor | If the inlet dust content >700g/m3 (standard),ash discharge device should choose big size screw conveyor or air slide conveyor | |||||||||

Soot Cleaning Program Controller | Input and output voltage both is 220v,controller is matching supplied by the manufacturer,please check the instruction for details | |||||||||

Filter Bag Size and Type | Diameter × length φ130×2450mm,Polyester fiber needled felt weight 450g/m2,Temperature 120℃ | |||||||||

Insulating Layer (m2) | 26.5 | 34 | 41 | 48.5 | 70 | 94 | 118 | 142 | 166 | |

Total Weight (about value, not include insulating layer)(kg) | 2400 | 3400 | 4400 | 5400 | 6900 | 8300 | 9700 | 11100 | 12500 | |

Note: 1. The purification filter area is the soot cleaning filter area in a room in the table.

2. The air consumption means the concentrate air supply in the factory, if set the stand-alone air compressor, the consumption in the table should multiply 1.3.

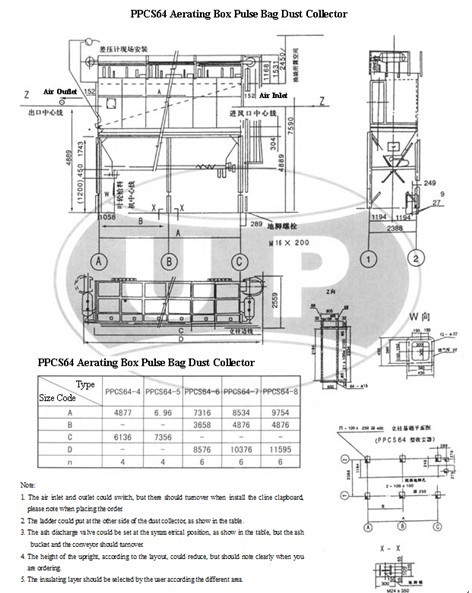

PPCS64 Aerating Box Pulse Bag Dust Collector