●General Information

Automatic high temperature cut-off valve is suitable for the secondary use of waste heat of boiler, furnace, blast furnace in building materials, mining, power, glass, light industry and other industry and waste gas and smoke pollution control of a variety of hot blast pipe. It is ideal equipment for energy-saving and high temperature gas switching.

●Structure Characteristics

Automatic high temperature Cut-off valve adopts stainless steel and carbon steel welding. It is double layer structure, the inner lining has a flame retardant, heat resistance materials. It has high temperature resistance, high efficiency, perfect structure, scientific and reasonable, flexible start and stop, convenient operation, etc.

The drive mode is split type and drive device is not subject to any form of control so that can be installed with the customer's needs. Drive form can be divided into winch lifting (switch signal), electric actuators lifting (4 ~ 20 mA current signal), electro-hydraulic, electric push rod (switch signal).

●Work Principle

The electric actuators to receive, change, adjust the control signal or operator hand control signal of DCS, PLC such upper gage. The output angular displacement driving shaft, the power to the valve shaft drives the butterfly plate for synchronous rotation; achieve the goal of full open and full close and arbitrary regulation. Electric actuator butterfly plate with the opening feedback 0-10 ma, or 4 to 20 ma dc current signal, the user can according to the current signal to control any opening of the butterfly plate, achieve the purpose of regulation. It will output the angular displacement to drive the transmission shaft, which will pass the power to the valve shaft to drive the butterfly valve synchronous rotary motion so that we change the direction and full close or full open as our wishes. The electric actuator and the gatage of the butterfly valve feedback the 10mA or 4~20mA DC signal at the same time. The customer can control the gatage of the diverter plate by controlling the electricity signal which can realize the adjustment.

●Technical Parameters

Nominal Pressure | Medium Flow Speed | Leakage Rate | Temperature | Medium |

0.05MPa | ≤25m/s | ≤1.5% | ≤450℃ | High gas like air, smoke, powdery material, etc. |

≤650℃ |

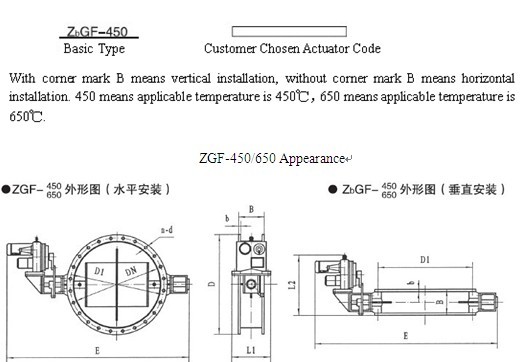

●Type Instruction

ZGF-450/650 External Connection Dimension

DN | D | D1 | B | b | n-d | E | L1 | L2 | n-d |

100 | 200 | 155 | 180 | 10 | 4-Φ14 | 855 | 450 | 620 | DKJ-210 T:100N.m P:0.025KW |

150 | 250 | 205 | 180 | 10 | 8-Φ14 | 905 | 450 | 620 | |

200 | 300 | 255 | 180 | 10 | 8-Φ14 | 965 | 450 | 620 | |

250 | 350 | 305 | 180 | 10 | 12-Φ14 | 1015 | 450 | 620 | |

300 | 400 | 355 | 180 | 10 | 12-Φ14 | 1085 | 450 | 620 | |

350 | 450 | 405 | 180 | 10 | 16-Φ14 | 1135 | 450 | 620 | |

400 | 520 | 465 | 200 | 12 | 16-Φ18 | 1385 | 500 | 650 | DKJ-310 T:250N.m P:0.065KW |

450 | 570 | 515 | 200 | 12 | 16-Φ18 | 1440 | 500 | 650 | |

500 | 620 | 565 | 200 | 12 | 20-Φ18 | 1486 | 500 | 650 | |

600 | 720 | 665 | 200 | 12 | 20-Φ18 | 1596 | 500 | 650 | |

700 | 820 | 765 | 220 | 12 | 20-Φ18 | 1780 | 600 | 700 | DKJ-410 T:600N.m P:0.16KW |

800 | 920 | 865 | 220 | 12 | 24-Φ18 | 1895 | 600 | 700 | |

900 | 1020 | 965 | 220 | 12 | 24-Φ18 | 1995 | 600 | 700 | |

1000 | 1130 | 1070 | 260 | 16 | 28-Φ22 | 2255 | 620 | 780 | DKJ-510 T:1600N.m P:0.4KW |

1100 | 1230 | 1170 | 260 | 16 | 28-Φ22 | 2355 | 620 | 780 | |

1200 | 1330 | 1270 | 260 | 16 | 28-Φ22 | 2455 | 620 | 780 | |

1300 | 1430 | 1370 | 300 | 16 | 32-Φ22 | 2555 | 620 | 820 | |

1400 | 1530 | 1470 | 300 | 16 | 36-Φ22 | 2655 | 620 | 820 | |

1500 | 1630 | 1570 | 300 | 16 | 36-Φ22 | 2770 | 620 | 820 | |

1600 | 1730 | 1670 | 300 | 16 | 40-Φ22 | 2870 | 620 | 820 | |

1700 | 1830 | 1770 | 340 | 20 | 40-Φ22 | 3110 | 650 | 900 | DKJ-610A T:2500N.m P:0.65KW |

1800 | 1930 | 1870 | 340 | 20 | 44-Φ22 | 3210 | 650 | 900 | |

1900 | 2030 | 1970 | 340 | 20 | 44-Φ22 | 3310 | 650 | 900 | |

2000 | 2130 | 2070 | 340 | 20 | 48-Φ22 | 3410 | 650 | 900 | |

2100 | 2230 | 2170 | 340 | 20 | 48-Φ22 | 3525 | 650 | 900 | |

2200 | 2330 | 2270 | 340 | 20 | 48-Φ22 | 3625 | 650 | 900 | |

2300 | 2430 | 2370 | 380 | 20 | 48-Φ22 | 3805 | 650 | 1000 | DKJ-610 T:4000N.m P:1.0KW |

2400 | 2530 | 2470 | 380 | 20 | 48-Φ22 | 3905 | 650 | 1000 | |

2500 | 2630 | 2570 | 380 | 20 | 52-Φ22 | 4005 | 650 | 1000 | |

2600 | 2730 | 2670 | 380 | 20 | 52-Φ22 | 4105 | 650 | 1000 | |

2700 | 2860 | 2785 | 420 | 24 | 56-Φ26 | 4210 | 750 | 1350 | DKJ-710 T:6000N.m P:1.5KW |

2800 | 2960 | 2885 | 420 | 24 | 60-Φ26 | 4310 | 750 | 1350 | |

2900 | 3060 | 2985 | 420 | 24 | 60-Φ26 | 4410 | 750 | 1350 | |

3000 | 3160 | 3085 | 420 | 24 | 60-Φ26 | 4510 | 750 | 1350 |

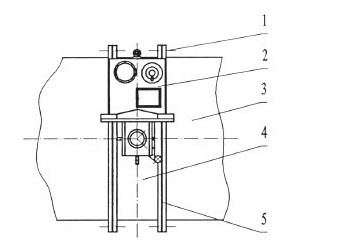

●Installation Instruction

1. Attachment Bolt 2. Actuator 3. User Pipe 4. Valve Body 5. High Temp. Gasket

●Installation and Test

1. Horizontal installation or vertical installation of the valve shaft should be on the same horizon level. The actuator should not be used for lifting and no damage.

2. Before installation, please clean the inside of the valve. There should no dirt and other things.

3. Please start and stop the valve for a cycle before installation, and adjust the valve according to the customer's work system (there was standard adjustment before leaving factory) ,if there is no problem, please full close the valve then install it.

4. When doing the manual operation, please cut off the power and there should no auxiliary lever added on the hand wheel. The clockwise of the hand wheel is turn on and the opposite direction is turn off. The range of the open angle is 0-90°.

5. The installation of the flange which connected with the valve, please check the picture. And please tighten the bolt evenly after added gasket. Please test the manual operation first then the electric transmission part.

6. After testing, please do the comprehensive check: Turn on the power then open and cut-off the valve. When the valve is full open and full close the travel switch should cut off the power exactly. And the torque limit part should at the edge of action. The gatage indicator should indicate the on-state of the valve. When switch between the manual and the electric institution, please cut off the power firstly.

●Transportation and Protection

1. During the transportation, please avoid the striking. Valve should keep close and in case of the butterfly plate and the transmission part damage in the transportation.

2. When the valve is transporting flatly, the transmission device and the drive part should overhead to prevent the out of shape and the damage of the transmission shaft under too much pressure.

3. The transmission device and part should add rain-proof and moisture-proof measures.

4. The valve should store in the dry room instead of putting in the opening air or pile up. If the diverter valve will in a long-term spare time, please keep them closed. The transmission device should add rain-proof and moisture-proof measures.

●Maintenance and Overhaul

1. Please check the work situation of the transmission parts regularly.

2. Please periodic replace the lubricating oil of the electric actuator so that it will ensure the mechanical parts won't get damaged.

3. Please periodic check the seal situation of valve's spindle regularly. If there question of the sealing, please replace or add the graphite packing.

4. Please check the gasket of the electro-hydraulic and pneumatic push rod so that it will ensure the normal running of the transmission device.

●Ordering Instruction

1. When placing the order, please refer to the sample's type, size, angle, technical parameters (temperature, equipment working conditions, medium, performance, etc.)

2. The transmission device in the picture of the sample is our basic equipment; if there is any special requirement (anti-explosion, outdoor, adjustable, switch, etc.), we could allocate other transmission device. Please refer to the allocation instruction attached with the samples to choose the transmission device, and mark behind the basic type.

3. When placing the order, if there is no special mark from the customers, the transmission code will be equipped the basic type of our company and the basic type is the normal device without any special requirement and accessories.

4. If there does not mark the type, use for special medium or other special requirements in the table, please contact with our sales and technical department. We could design and manufacture.