●Characteristic

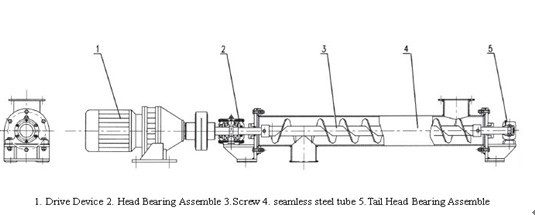

LS screw conveyor (hereinafter referred to as the screw machine) new structure, advanced technical indicators, moves the head, the tail bearing out of the shell, the middle bearing can swap two structures between rolling and sliding, and both the two have dust-proof sealing device. The discharge end is equipped with cleaning device. The whole machine is low noise, strong adaptability, convenient operation and maintenance, and inlet and outlet position is arranged flexibly.

●Scope of Application

Screw machine is widely used in various industrial sectors, such as building materials, electric power, chemical industry, metallurgy, coal, aluminum, magnesium, machinery, light industry, grain industry. It is suitable for horizontal or less than 20 ° inclination, conveying powder, granulated and small lump materials, such as cement, coal, grain, chemical fertilizer, ash, sand, etc., the material temperature below 200 ℃.

Screw machine should not transport perishable, viscous and easy to agglomerate materials, because these materials will bond on the screw when conveying, and then rotate with screw and does not move forward or block the suspension bearing formation, and make the screw machine can't work normally.

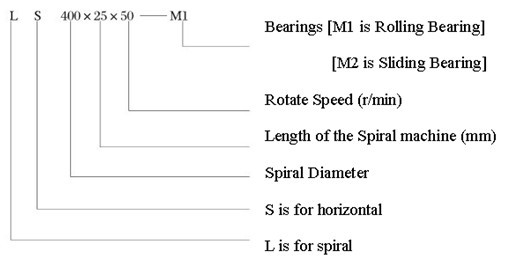

LS screw machine screw diameter from 100 mm to 800 mm, a total of nine kinds of specifications, the length from 4 meters to 70 meters, one every 0.5 meters, conform to the standard model selection of the nominal length, special needs can be separately in the matching section is put forward.

According to the rotating machine driving mode is divided into two kinds:

C1 method - screw machine length is less than 35 m, single-end driver.

C2 method - screw machine is more than 35 m, double-end diver.

According to the screw machine middle suspension bearing types are divided into:

M1 - rolling bearing, using 80000 type sealed bearing, shaft cover another dustproof sealing structure, commonly used in is not easy to add oil, no oil or oil is the pollution to material, the sealing effect is good, hanging bearing life is long, conveying material temperature of 80 ℃ or less (when you order it does not need indicate).

M2 - sliding bearing, using dust-proof sealing device, commonly used in conveying material temperature is quite high (> 80 ℃), or transporting materials in liquid.

LS Screw Conveyor Type and Technical Parameters

Type | 200 | 250 | 315 | 400 | 500 | H | K | J | M |

Screw Pitch | 200 | 250 | 315 | 355 | 400 | 3 | 9 | 4.36 | GX20-10-00 |

n | 100 | 90 | 80 | 71 | 63 | 4 | 9 | 7.52 | GX25-10-00 |

Q | 13 | 22 | 31 | 62 | 98 | 4 | 13 | 9.36 | GX30-10-00 |

n | 80 | 71 | 63 | 56 | 50 | 4 | 13 | 14.28 | GX40-10-00 |

Q | 10 | 18 | 24 | 49 | 78 | 4 | 17 | 26.14 | GX50-10-00 |

n | 63 | 56 | 50 | 45 | 40 | 6 | 17 | 39.2 | GX60-10-00 |

Note:1. n——Rotate Speed r/min(Deviation≤ 10%);

2. Q——Convey Capability m3/h。

2. Q——Convey Capability m3/h。

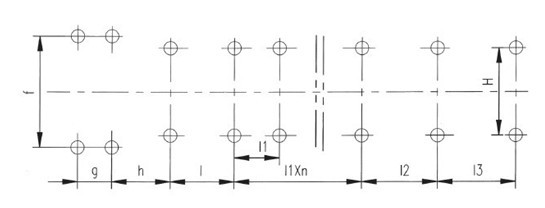

Outline Dimensional Drawing and Size List

ΦD | F | E | W | I | I1 | I3 | Screw Choose Length G | Relative Corner Size l2 | Q | Y | L | ||||

LS200 | 2500 | 2500 | 2500 | 2480 | 2500 | 2640 | 500 | 2000 | 2500 | 1500 | 2000 | 2500 | 225 | 180 | 112 |

LS250 | 3000 | 3000 | 3000 | 2980 | 3000 | 3140 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | 250 | 200 | 140 |

LS315 | 3000 | 3000 | 3000 | 2980 | 3000 | 3140 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | 330 | 220 | 180 |

LS400 | 3000 | 3000 | 3000 | 2980 | 3000 | 3140 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | 340 | 227 | 224 |

LS500 | 3000 | 3000 | 3000 | 3000 | 3000 | 3160 | 2000 | 2200 | 3500 | 2000 | 2200 | 3500 | 400 | 250 | 280 |

ΦD | K | R | S | Z | O | H | V | J | e | p | T | d | L4 | Key b×h |

GB1036-79 | ||||||||||||||

LS200 | 180 | 225 | 180 | 60 | 320 | 160 | 200 | 14 | 280 | 60 | 212 | 40 | 82 | 12×8 |

LS250 | 224 | 250 | 224 | 70 | 370 | 200 | 270 | 18 | 285 | 60 | 240 | 50 | 82 | 14×9 |

LS315 | 280 | 390 | 250 | 80 | 443 | 300 | 300 | 20 | 320 | 60 | 340 | 60 | 105 | 18×11 |

LS400 | 355 | 390 | 280 | 90 | 352 | 320 | 400 | 24 | 390 | 60 | 384 | 80 | 130 | 22×14 |

LS500 | 400 | 400 | 340 | 105 | 653 | 400 | 500 | 24 | 397.5 | 80 | 440 | 90 | 130 | 25×14 |

General arrangement of screw conveyor:

A screw machine often follow the order: drive device, head quarter, several standard middle quarter, selective middle quarter, and tail quarter. Except the head quarter casing and selective quarter, other quarter's spiral and casing are interchangeable, and there is cleaning device at discharge end screw , when installation, pay attention to the position.

Drive device is a Planetary Cycloidal pinwheel reducer motor (or JTC reducer motor) or choose JZQ reducer. Head quarter is equipped with thrust bearing, affordable to axial force when material is moving, head quarter casing with suspension bearing and chassis inside, each middle quarter with a hanger bearing is used to support the screw axis, a centripetal ball in hanger bearing (or integral sliding bearing), in the end quarter is equipped with rolling (slide) bearing added to support the screw axis and screw length error, when installation should begin from the head quarter, and successively.

In overall arrangement, should pay attention to don't make the base and the discharging mouth is decorated in the casing interface flange, inlet should not be arranged above the hanger bearing, if open mouth affects the arrangement of the base and can't follow this principle, the use of units should draw the spiral machine assembly drawing.

1. Drive Device and the Foot Size

(1) The reducer chooses the XWD drive device.

2. Feed Inlet and Discharge Outlet

The feed inlet and the discharge outlet are opened by customer at the working position. Generally feeding from the tail and the discharge from the end and the opposite way is OK too. If there is need to feed in the middle and discharge from the both ends or the opposite way, the brief drawing should be sent to us with the order.

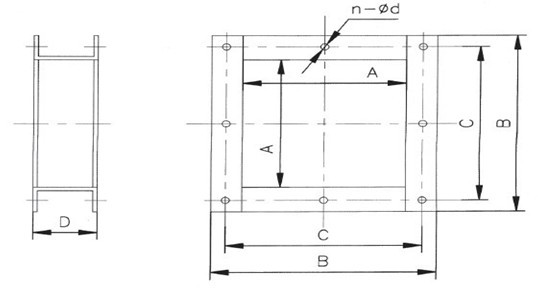

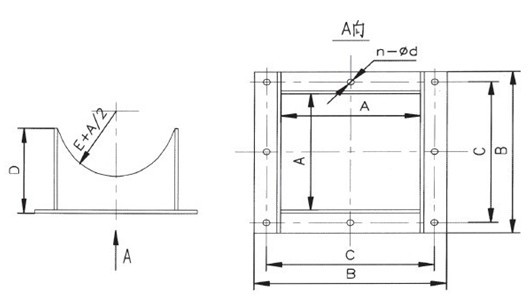

(1) Feed Inlet

Inlet structure shown as the following picture, the feed inlet is used to connect the spiral machine and the feed hopper, its cover button cover clamps the casing in the machine, also can use welding method is combined with machine casing, feed inlet should open in the machine according to the size of inlet hole.

The external and install dimension of the feed inlet

Type | Appearance and Installation Dimension (mm) | |||||

A | B | C | D | d | n | |

LS200 | 200 | 300 | 256 | 100 | 14 | 8 |

LS250 | 250 | 350 | 306 | 100 | 14 | 8 |

LS315 | 315 | 415 | 370 | 160 | 14 | 8 |

LS400 | 400 | 500 | 456 | 160 | 14 | 8 |

LS500 | 500 | 600 | 558 | 160 | 14 | 12 |

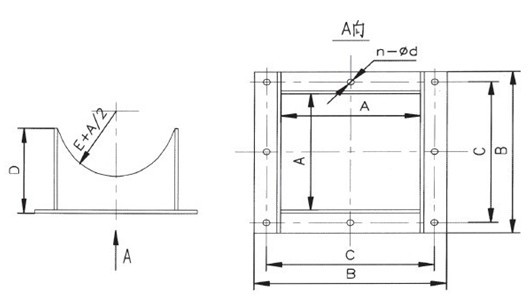

(2)Discharge Outlet

Discharge Outlet's structure is as following picture, it is made of the square tube blended by the steel and the flange welded together, it has no discharging mouth control institutions, welding discharge mouth on the casing when start to use, and the flange surface combined with chute flange, assemble discharge outlet should also according to the discharging mouth of the mouth of the inner hole size open hole

The external and install dimension of the discharge outlet

Type | Appearance and Installation Dimension (mm) | |||||

A | B | C | D | E | d | |

LS200 | 200 | 300 | 256 | 180 | 14 | 14 |

LS250 | 250 | 350 | 306 | 224 | 14 | 14 |

LS315 | 315 | 415 | 370 | 250 | 14 | 14 |

LS400 | 400 | 500 | 456 | 280 | 16.5 | 14 |

LS500 | 500 | 600 | 558 | 340 | 16.5 | 14 |

PS: Our factory also improve production the original LS screw conveyor with GLS series tubular screw conveyor, its has great improvement of sealing performance and control of material compare with LS screw conveyor, especially suitable for conveying various powdery material with liquidity better and its structure as shown in figure below: