●Applied Range

1. DT75 belt conveyor is for general-purpose, mainly used in mining, metallurgy, chemical, coal, building materials, machinery, grain, light industry, water and electricity, transportation and other departments, it is suitable for conveying the bulk specific weight is 0.5 ~ 2.5 t/m3 of various shapes and granular material, also suitable for transport goods into pieces.

2. DT75 belt conveyor transmission bandwidth has six kinds: 500, 650, 800, 1000, 1200 and 1400 mm.

3. Belt selected for DT75 belt conveyor has ordinary rubber belt and plastic tape, suitable for working environment temperature between 15 ℃ ~ + 40 ℃. When delivering materials' ingredients are acidic, alkaline, oil substances and organic solvent, please choose the oil resistant, acid and alkali resistant rubber belt or plastic belt.

4. It can be used for horizontal or inclined conveying, inclined upward transportation, the max inclination angle β allowed by different materials are shown in table 1, and the allowed maximum angle of downward sloping delivery is 80% of the values listed in table 1. If need to use table 1 is greater than the inclination in table 1, can choose the figured-belt conveyor.

Table 1

Material Name | β | Material Name | β |

Lump coal | 18° | Wet Concentrate(water contain12%) | 20°~22° |

Raw coal | 20° | Dry Concentrate | 18° |

Pulverized coal after wash products (1) | 21° | Carboniferous rock after screening | 12° |

Coke after screening | 17° | Dry Sand | 15° |

0~25 mm Coke | 18° | Sand with gravel | 18°~20° |

0~3 mm Coke | 20° | Sand from quarry | 20° |

0~350 mm ore(2) | 16° | Wet Sand | 23° |

0~120 mm ore | 18° | Salt | 20° |

0~60 mm ore | 20° | Foundry sand | 24° |

40~80 mm oil shale | 18° | Waste sand | 20° |

20~40 mm oil shale | 20° | Stone without screening | 18° |

0~200 mm oil shale | 22° | cement | 20 |

Dry and loose Soil | 20° | Bulk dry clay | 15°~18° |

Wet soil | 20°~230° | Powder dry clay | 22 |

Note: (1) Include concentrate, middling coal, tailings.

(1) Include ferrous metal, nonferrous metal, rock stone, limestone and other mineral stone.

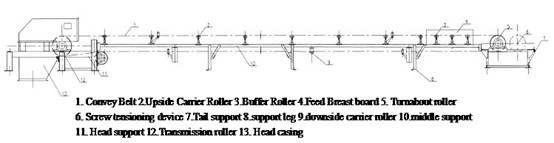

●Parts Name

Belt Width mm | Belt Speed m/s | Max Convey Capability Groove/Flat | Max Dip Angle |

500 | 0.8,1,1.25, 1.6,2,2.5 | 232/125 | 20° |

650 | 391/211 | ||

800 | 1,1.25,1.6,2,2.5,3.15 | 824/350 | |

1000 | 1233/546 | ||

1200 | 1,1.25,1.6,2,2.5,3.15,4 | 2202/821 | |

1400 | 2996/1117 |

Note: Max convey capability is calculating with material capacity r=1.0t/m,dip angle of conveyor β=0°~6°, material stack angle ρ=30°

●Operation of Belt Conveyor

1. Please do the first test by empty device and adjust belt. And please notice if there any failure occurrence.

2. After empty load test, if it is in good condition, please do the full load test in accordance with equipment's standard and check if the running is OK and the temperature of bearing is rising. If everything is all right, it could be used in the real work condition.

3. Conveyor must be no-load start-up, and should start first then feed. If there are several conveyors combined, first start is the discharge end and the follow the order, the stop should after the discharge is finished.

4. Please don’t load the over standard rock and other heavy materials on the belt ,otherwise heavy objects will be make the belt down or damaged parts.

5. When feeding, can't make delivery material falls on the belt from high place.

6. If more than one conveyor used in combination, its electrical switch must be interlocked, so that the end conveyor will last stop.